Manufacturing

RAW MATERIALS

The basic materials for the manufacturing of our candles are of high quality to ensure good combustion, without smoke, residue, and unpleasant odors. We use refined paraffin, vegetable oils, the finest essences soluble in paraffin, pigment-based colorants, and pure bleached and waxed cotton wick.

Ceras Roura is part of the Board of Directors of the ASSOCIATION EUROPEAN CANDLE MAKERS, based in Brussels. This organization is composed of the leading European candle manufacturers and oversees the quality and safety standards set by the E.E.C. to offer consumers guaranteed products.

PRODUCTION PROCESSES

- Reception and storage of liquid paraffin and vegetable oils in insulated tanks

- Preparation of formulations incorporating colorants and perfumes.

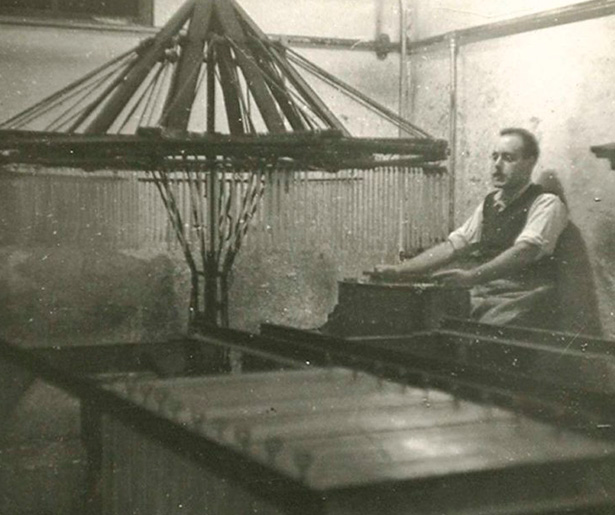

- Transformation of the liquid into powder through a spray and cooling process on water-cooled rotating cylinders at 4ºC.

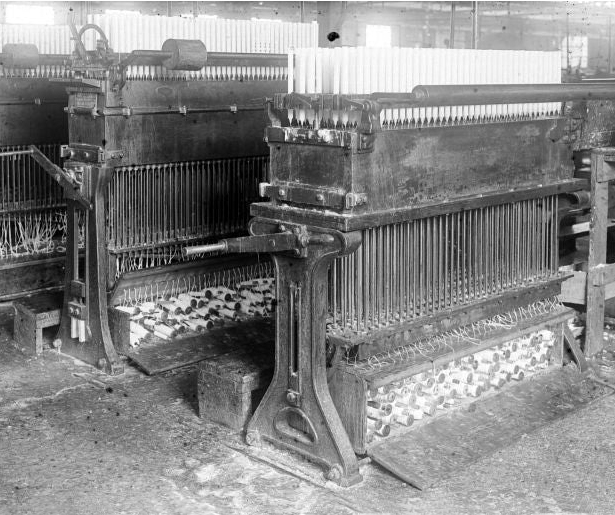

- Aspiration of the powdered paraffin for pressing or extruding, depending on the type of candles to be manufactured.

- Other products are obtained through molding machines, aluminum molds, and immersion baths.

- The final finishing of the product, which can be scented, metallized, etc., is achieved through coloring or varnishing - Automatic line for filling all types of containers.

- Finally, after being labeled and packaged, the items are boxed and sent to the finished product warehouse, refrigerated at 23ºC.